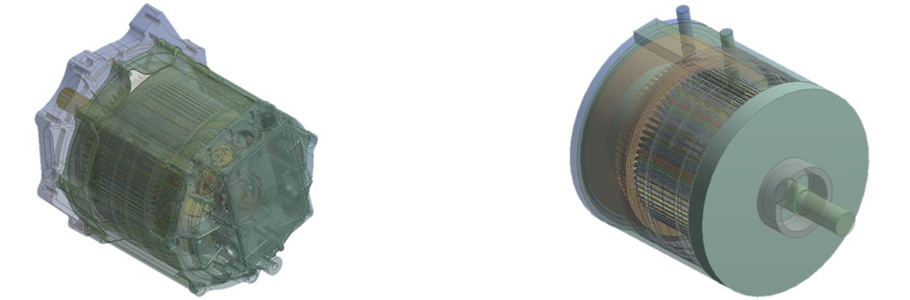

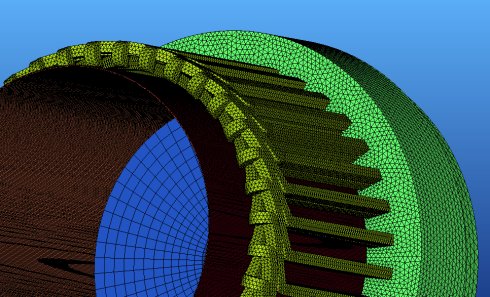

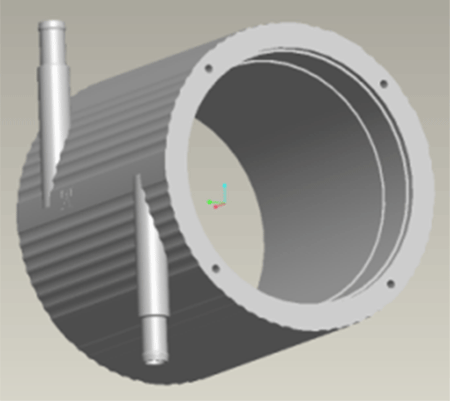

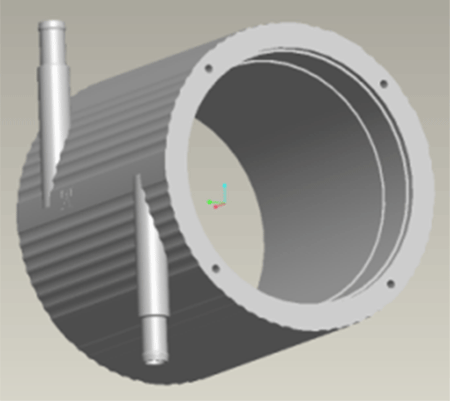

Extruded aluminum motor housing has an extensive application due to the advantages of higher strength, lightweight, and better cooling performance. Moreover, it meets the cosmetic requirements on the surface and it not only resists to corrosions but also requires no further machining on the internal surface. It is not only smaller in volume but also lightweight with a simpler structure which is easy to install and maintain. The production process is very eco-friendly and the production throughput is higher. It is easier for transportation and storage and thus it is favored by a variety of electric motor manufacturers.

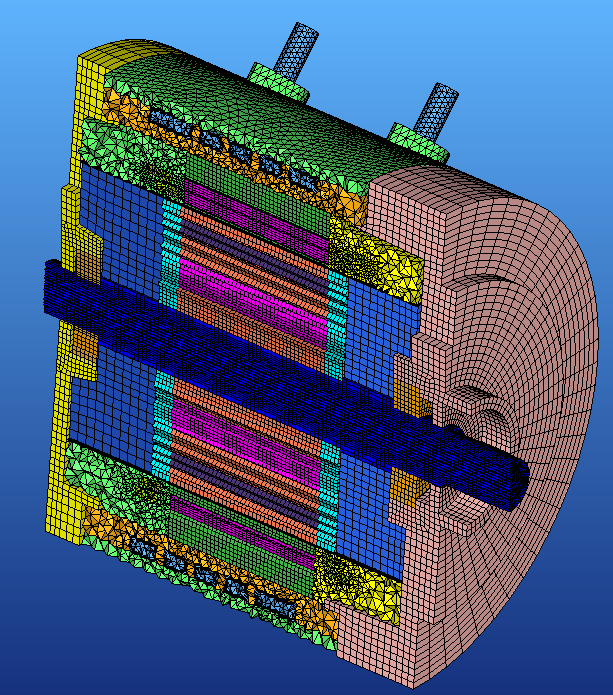

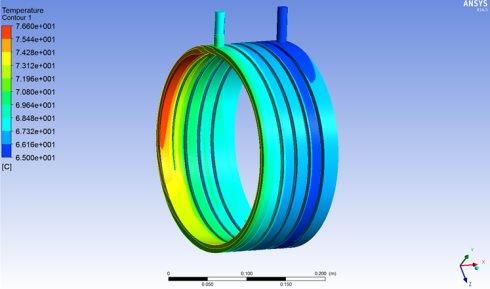

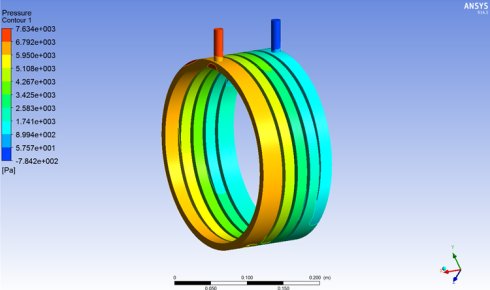

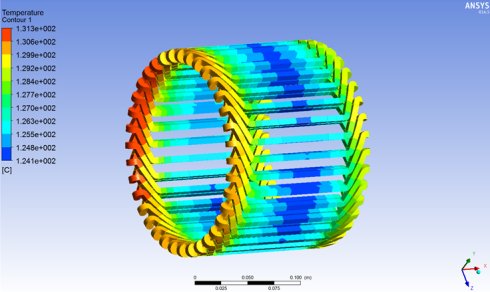

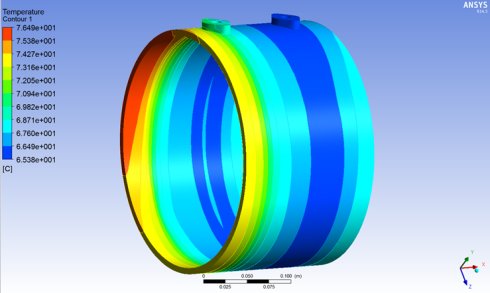

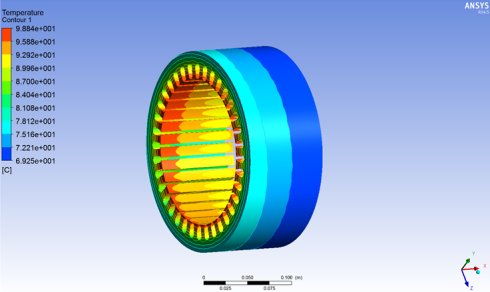

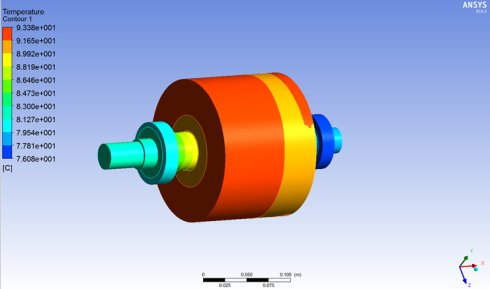

Winshare Thermal is a high power manufacturer who specializes in the thermal management of various parts. In the motor housing field, Winshare Thermal engineers have been trained to consider the cooling requirements during the earlier stage of a motor housing design. We design the shape of a motor housing and the profile and size of fins based on the cooling requirement of the electric motor. When there are particular environmental constraints, we will include several cooling techniques for a design including forced air cooling, liquid cooling, etc.

Extruded aluminum motor housing has an extensive application due to the advantages of higher strength, lightweight, and better cooling performance. Moreover, it meets the cosmetic requirements on the surface and it not only resists to corrosions but also requires no further machining on the internal surface. It is not only smaller in volume but also lightweight with a simpler structure which is easy to install and maintain. The production process is very eco-friendly and the production throughput is higher. It is easier for transportation and storage and thus it is favored by a variety of electric motor manufacturers.

Extruded aluminum motor housing has an extensive application due to the advantages of higher strength, lightweight, and better cooling performance. Moreover, it meets the cosmetic requirements on the surface and it not only resists to corrosions but also requires no further machining on the internal surface. It is not only smaller in volume but also lightweight with a simpler structure which is easy to install and maintain. The production process is very eco-friendly and the production throughput is higher. It is easier for transportation and storage and thus it is favored by a variety of electric motor manufacturers.